Capacity: 50kg/h-500kg/h

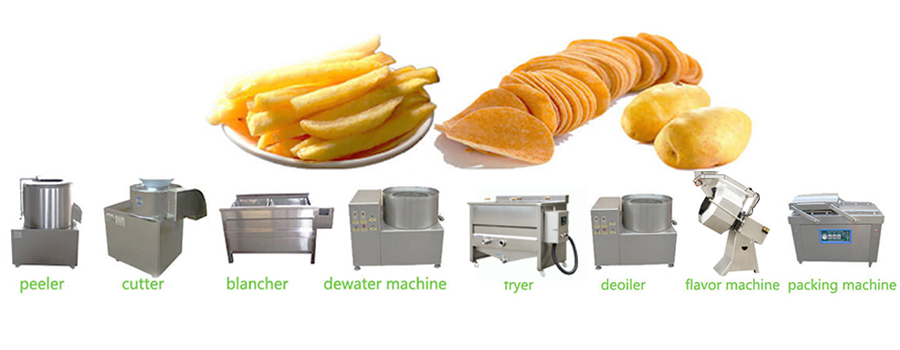

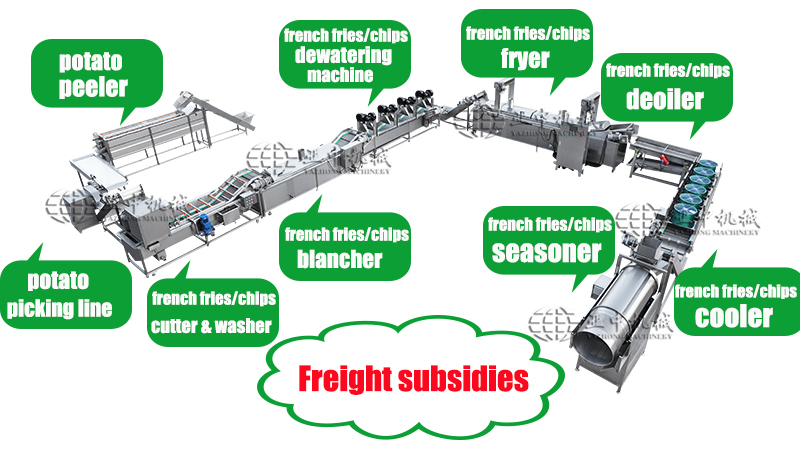

Washing and peeling- cutting-blanching- dewatering-frying-deoiling-drying-flavoring-packaging

Cassava chips production line is to produce delicious cassava chips from cassava tubers. Cassava chips are also known as tapioca chips, manioc chips and yuca chips in different countries. In light of these variant of names, we can tell the cassava chips are popular. And with various added flavors, tapioca chips are becoming more and more popular, just like potato chips and banana chips. Due to this rising popularity, cassava chips making industry is of great margins. In other words, cassava chips making business is a profitable one. If you want to step into the manioc chips making business, or expand your existing business, please do not hesitate to contact us. For we are professional supplier and manufacturer of cassava chips making machines, we offer turnkey solutions for your chips line as well as quality chips making machine.

As a kind of root vegetable, cassavas are processed into chips just like producing potato chips from potatoes. To obtain optimum end product, each process is vital in itself.

At first, when the cassavas arrive at factory, they are sorted and graded, removing defective ones. This sorting and grading process can be done both mechanically and manually. At times, workers will trim or cut the cassavas into halves if they are too big to process. Our sorting and grading machine can do the job effectively and efficiently.

Then the cassavas will be washed and peeled. For small scale cassava chips production, this washing and peeling process can be done by human labor, while machines are used in large scale cassava chips plant. For our washer and peeler, it is integrated into one machine. With roller brushes and spraying water, the washer and peeler can do the job in an effective way with less use of energy.

The washed and peeled cassavas will be cut into thin slices with regular shapes. Usually the cassava slices are often soaked into water when they are cut. Our cassava cutting machine can cut cassavas into thin slices with uniform shapes and adjustable thickness.

Then the following step is to blanch these cassava slices. Blanching is important in that it can remove extra starch, preserve desirable color, and eliminate potential bacteria. Our blancher machine allows you to control the temperature of water and blanching time.

Since there is extra water on surfaces of cassava chips after blanching, it is necessary to dry them up before frying. Our dehydration machine uses vibration system, which can drain off water without damage to the cassava chips.

The next is frying process, in which cassava slices are deep fried in high temperature oil. Our cassava chips fryer machine allows for precise oil temperature control, adjustable belt speed, and fast removal of particles. All these combined can ensure you get quality end products with less use of water and energy.

Since there is extra oil on the surface of fried cassava chips, it is necessary to remove it by de-fatting machine. Through vibrating, our deoiling machine can remove extra oil effectively with minimum damage to the products.

To make them delicious, flavors are added to plain cassava chips. Our flavoring mixer machine can spread the flavors evenly on the products, due to its smart design.

The final stage is packing. It is vital for prolonging product shelf life, it can also serve as a strong promotion tool. Our cassava chips packaging machine can pack the cassava chips efficiently with no damage to the products.

Obviously, there are two types for your choice according to your capacity, budget and other factors.

For a beginner and people who have low buget, this type is the best solution for you. In term of capacity, it is about 50kg/h to 100kg/h. Absolutely, it can meet the need for small scale potato chips, french fries and cassava chips plant.

This cassava chips line has high automaticon compared with semi automatic cassava chip line. As for people who have a lot of experience in food industry, this type is very suitable for you. At the same time you can have enough budget to support your business. There are much advantages for your reference: reducing labor cost, high capacity at high speed, better quality for banana chips, easy to control temperature and time. If you want to save time and reduce extra work, this is the perfect solution for your choice.

As for the cassava chips making machines prices, since they are all made in our own factory, we can offer your reasonable prices than competitors.

Customer design: While you can choose from our various machines, we also provide tailored turnkey solutions and customer designed machines to meet your needs and requirements.

Quality machines: The cassava chips making machines in our factory are all made of high quality food grade stainless steel. This makes the machines durable and sanitary.

Ease maintenance: Due to advanced technology and smart design, our cassava chips making machines are easy to clean and maintain, reducing down time.

Competitive prices: The machines for tapioca chips making line are all designed and manufactured in our own factory, which save you from third party fees.

1. It is suitable for large and small potato chips, Cassava chips, banana chips,coconut chips and other processing workshop. According to your workshop area, we offer the best solutions to bring big benefits to you.

2. It can process all kinds of fruit and vegetable, especially root vegetables.

|

No. |

Name |

Quantity |

|

1 |

Elevating Conveyor |

1 set |

|

2 |

Cassava Washing and Peeling Machine |

1 set |

|

3 |

Cassava Picking Line |

1 set |

|

4 |

Cassava Cutting/Slicing Machine |

1 set |

|

5 |

Cassava Chips pre washing machine |

1 set |

|

6 |

Cassava Chips roller picking machine |

1 set |

|

7 |

Cassava chips Bubble Washing Machine |

1 set |

|

8 |

Cassava chips Blanching Machine |

1 set |

|

9 |

Cassava chips Air Drying Machine |

1 set |

|

10 |

Cassava chips Elevating Conveyor |

1 set |

|

11 |

Continuous Belt Frying Machine |

1 set |

|

12 |

Cassava chips Vibrating Deoiling Machine |

1 set |

|

13 |

Cassava chips Air Drying Machine |

1 set |

|

14 |

Elevating Conveyor |

1 set |

|

16 |

Automatic Packing Machine |

1 set |

Fully Automatic Banana Chips Production Line

Semi-Automatic French Fries Potato Chips Production Line

Vegetables and Fruit Processing Line

Full Automatic French Potato Chip Production Line