Capacity:50kg/h-500kg/h

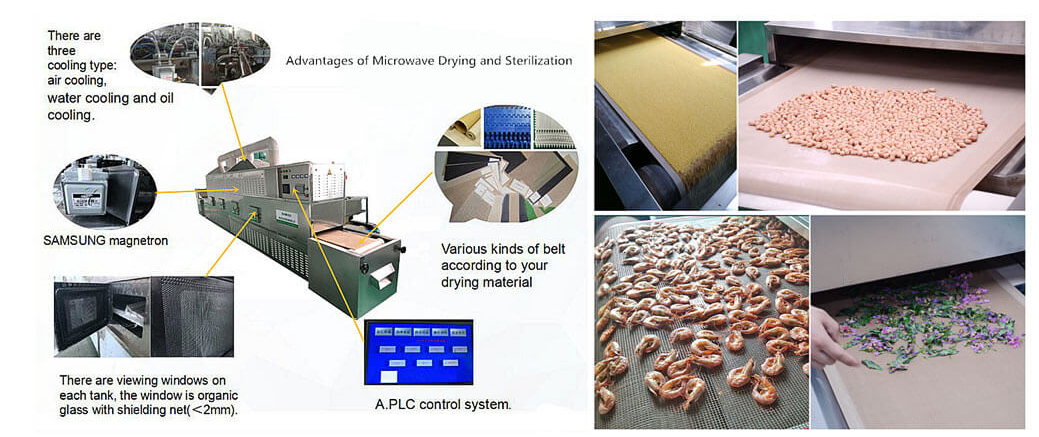

It can be used for drying, puffing, baking products, sterilization and other processing, such as: black beans, soybeans, barely, oats, buckwheat, mung bean, red bean, cowpea red bean.

Spices: hot pot bottom material, spices, pepper, aniseed, fennel, anise, geraniol, cinamon, chilli powder, curry powder, five spice powder and ther condiments drying and sterilization production.

Marine products: fish, shrimp, etc.

It can be used for drying, puffing, baking products, sterilization and other processing, such as: black beans, soybeans, barely, oats, buckwheat, mung bean, red bean, cowpea red bean. Spices: hot pot bottom material, spices, pepper, aniseed, fennel, anise, geraniol, cinamon, chilli powder, curry powder, five spice powder and ther condiments drying and sterilization production.

Marine products: fish, shrimp, etc.

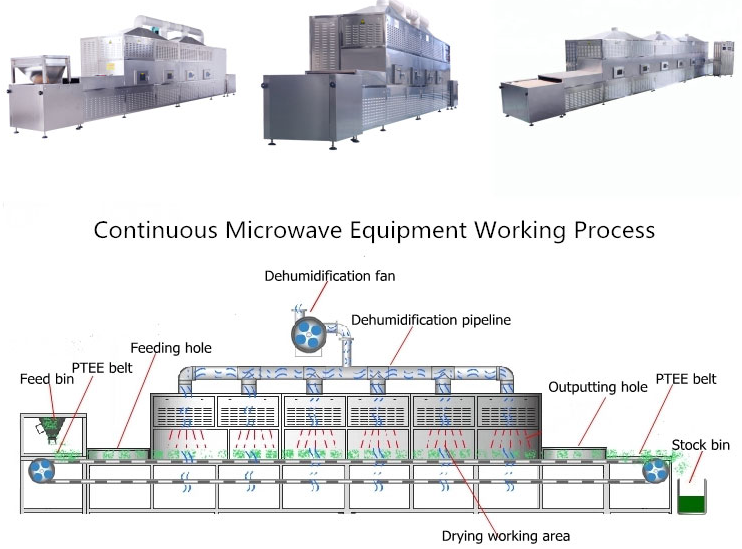

Macrowave baking is the heated material is used as a heater, microwave baking can be instantaneous into the material does not need to be heated at the samen time, the heat conduction process, so the temperature is going up fast, greatly shorten the heating time 1/4 than the general conventional method.

Microwave are electronmagnetic waves at frequencies from 300MHz to 300000 trillion Hz. The material in the heating medium in the molecule of water is a polar molecule, it in the rapidly changing under high frequency magnetic field, its pilarity orientation will be with change of external electric field changes, resulting in molecular motion and friction between the effect. This field of the microwave can transform into thermal energy within the medium, the temperature of the material increased, heating and puffing a series of physical and chemical processes, so as to achieve the purpose of the microwave heating and drying.

The energy conversion efficiency is high, the heating speed is fast.

Microeave oven it self does not heat, but ht emicrowave energy through the material, so that the material inside the polat molecules of mutual friction and heat. So there is no energy loss.

Expansion effect is obvious. Microwave heating effect, so that the material inside the water molecules fast vaporization, to achieve the purpose of expanding.

Low temperature sterilization, less loss if nutrients. Microwave sterilization was carried out under the double actiion of the heat effect and temperature sterilization effect could be satisfied.

Easy to use. The microwave power and the transmission belt speed can be continuously adjusted, thre is no thermal inertia, which can be opened or stopped, and is simple and easy to control.

Parameters of microwave drying machine

|

Model |

AC-20HMV |

AC-40HMV |

AC-60HMV |

AC-100HMV |

AC-200HMV |

|

Frequency |

2450±50MHZ |

2450±50MHZ |

2450±50MHZ |

2450±50MHZ |

2450±50MHZ |

|

Input power |

≤25KW |

≤50KW |

≤75KW |

≤120KW |

≤240KW |

|

Microwave output power |

≥20kw |

≤40KW |

≤60KW |

≤100KW |

≤200KW |

|

Working temperature |

70-200℃(undercontrol) |

70-200℃(undercontrol) |

70-200℃(undercontrol) |

70-200℃(undercontrol) |

70-200℃(undercontrol) |

|

Cooling mode |

Hydrocooling/air cooling |

Hydrocooling/air cooling |

Hydrocooling/air cooling |

Hydrocooling/air cooling |

Hydrocooling/air cooling |

|

Working time |

24hour |

24hour |

24hour |

24hour |

24hour |

|

Inlet&outlet |

40-100mm |

40-100mm |

40-100mm |

40-100mm |

40-100mm |

|

Transmission belt height |

600-1000mm |

600-1000mm |

600-1000mm |

600-1000mm |

600-1000mm |

|

transmission speed |

0-4.5m/min |

0-4.5m/min |

0-4.5m/min |

0-10m/min |

0-10m/min |

|

dehydration rate |

16-20kg/h |

30-40kg/h |

48-60kg/h |

80-100kg/h |

160-200kg/h |

|

Dimensions(mm) |

8640*1220*2200 |

10960*1500*2200 |

13200*1500*2200 |

15600*1700*2200 |

22560*1900*2200 |

|

Conveyor belt width |

500±100mm |

800±100mm |

800±100mm |

1000±100mm |

1200±100mm |

|

Microwave leakage standard |

national standard |

national standard ≤5mw/cm2 |

national standard ≤5mw/cm2 |

national standard ≤5mw/cm2 |

national standard ≤5mw/cm2 |

Raw material:

1. It is suitable for cutting leafy vegetable, such as: cabbage, spinach, pepper, etc.

Root vegetable: potato, taro, onion, sweet potato, eggplant, melon etc.

Fruit: apples, strawberries, jujubes, blueberry another fruit cleaning.

Spices: hot pot bottom material, spices, pepper, aniseed, fennel, anise, geraniol, cinamon, chilli powder, curry powder, five spice powder and ther condiments drying and sterilization production.

Grain: black beans, soybeans, barely, oats, buckwheat, mung bean, red bean, cowpea red bean etc.

Marine products: fish, shrimp, etc.

2. Small food processing plant, snack food factory, fruit processing plant.

3. Hotels, food & Beverage factory, farms, restaurant.

Fried Puffed Snack Food Processing Line

Nutritional Rice and Instant Rice Production Line

Pet Food Production line

Breakfast Cereal and Corn Flakes Production Line